Calibration Equipment Explained (ARTICLE)

Dust Maintenance

R20 Dust Monitor Service kit – One service kit should be sufficient for a fleet of instruments, however if instruments are being deployed to different sites we would suggest one service kit per site. Some of the consumables in the kit (e.g. O-rings, Luer fittings, tube) will need to be replaced periodically but other items like the screwdriver should last for the useful life of the instrument.

Spares for items in this kit are below:

- R8 Flowmeter - used for routine service i.e. measuring and adjusting the PM sample flow rate.

- R23 Leak Gauge – used to test the leak tightness of the system after carrying out routine servicing/maintenance

- R56 Zero filter & Flow assy - used to perform a zero check on the PM engine during routine service and maintenance.

- CS TUBE10 Tygon tube – Aeroqual recommend replacing Tygon tubing when you send the optical engine for factory calibration (i.e. 2 years for Nephelometer based PM systems).

- O-RING04 PM inlet O-Ring - For typical applications a client would expect to go through 1 or 2 O-rings per instrument per year. This number might be lower if the inlet assembly is not being disassembled/reassembled frequently (e.g. long term monitoring opposed to short term rental applications)

R10 Sampling Pump – sits inside the system (one for dust one for gas in a dual system), it’s the pump used to draw the sample air through the optical engine (i.e. Nephelometer or OPC) in the instrument. Pumps are long-life high quality BLDC diaphragm type by KNF with lifetime 1-3 years. They will only require replacement when they are no longer capable of maintaining an adequate sample flow rate.

R30 47mm Filters – only needed if taking and analyzing dust samples.

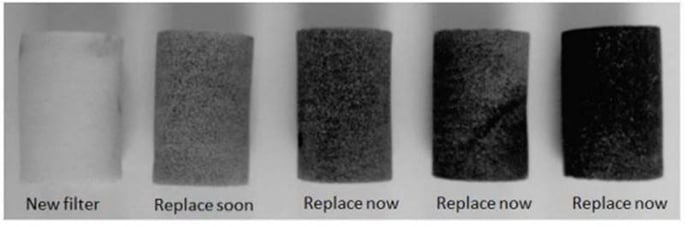

R31/R32 PM Filters – average service checks and filter replacements for typical applications are 3-monthly, but for the sake of practicality, it might be best to assess filter replacements on colour (see image below) rather than timeframe as installation sites differ significantly from location to location.

Dust Calibration

- CAL R4 Factory Calibration – every 2 years for Nephelometer based systems. Send to MetOne in USA (but contact Aeroqual when this service is required so they can assist)

- CAL R5 Factory Calibration – every year for OPC (profiler) systems. Send to MetOne in USA (but contact Aeroqual when this service is required so they can assist)

Gas Maintenance

- R10 Sampling Pump – sits inside the system, one for dust and one for gas in a dual system. Pumps are long-life high quality BLDC diaphragm type by KNF with lifetime 1-3 years. They will only require replacement when they are no longer capable of maintaining an adequate sample flow rate.

- R12 Inlet Filters for gas – pack of 25, change filters every month, so approx. 2yr supply. One filter per AQS 1 system

- R35 PID Lamp polishing kit – can be used on multiple lamps, repeatedly.

- R48 PID Lamp – consumable in the PID and cheaper to replace than the PID sensor. Specified life is 5,000 hours which translates to 6-12 months depending on operational and environmental factors. Not the easiest item to service but Aeroqual can train us. See below tech note.

- <<Technical-Note-PID lamp replacement procedure.pdf>>

Gas Calibration

The Aeroqual gas modules in the unit do not require factory calibration. For typical monitoring applications our clients perform calibration checks at 3-6 month intervals. It can be done in the field or at your labs / office.

Calibration frequency is dictated by:

- data quality objectives

- environmental and operational factors

- local regulatory requirements (if applicable).

- Budget

- R101 AirCal 1000 – to be used in the field or by Specto in our workshop. Includes a zero air generator but also requires gas cylinders. Scrubber media will need replacing periodically (e.g. 6-12 months) depending on use.

- R111 Zero Air Scrubber - part of the Aircal 1000. Replace every 6-12 months depending on use

- Gas cylinders – IsoB for VOCs, CO, NO2, etc. (one bottle for every gas except Ozone).

- AIC GASREG01 Gas regulator for AIRCAL 1000 – fits to gas cylinders with C10 fitting and to AIRCAL 1000 with a Swagelok fitting

- R7 Flowmeter Kit – a high spec flow meter capable of measuring low flow rates accurately (e.g. <100ml / min). It’s required for checking the flow rates of individual gas modules in the AQS1. To be used in the field or by Specto in our workshop.

- O3CAL Ozone Cal Source - to be used in the field or by Specto in our workshop.

- R41 Calibration gas humidifier kit, including nafion tube - Required if field calibrations are to be done using a zero-air gas cylinder instead of Aircal1000. Note: cannot use 100% N2 for zero air.

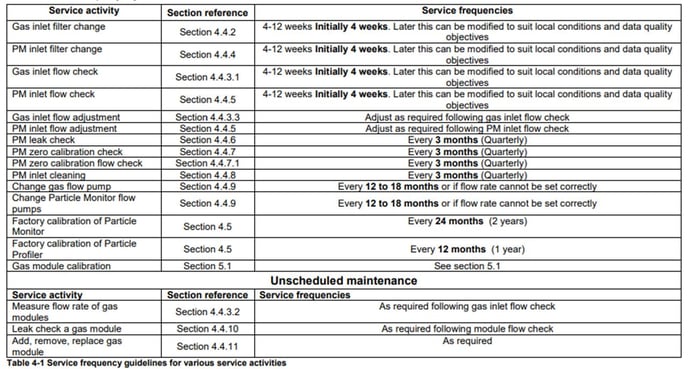

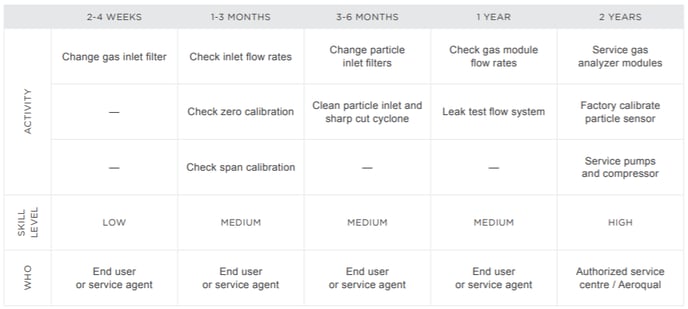

Here is an example of scheduled maintenance for a typical AQM 65 system comprising multiple gas and particulate measurements.

Handheld Calibration

- CAL R1 – Factory calibration for Ozone sensor heads. Recommended to be done in factory every year.

- CAL R2 – Factory calibration for all other sensor heads. Recommended to be done in factory every year.

If a more frequent field calibration is required, you can perform a bump test/calibration of the sensor heads using an Aircal 1000 and AS R42 Calibration Accessory

- AS R42 Calibration Accessory - use with Aircal 1000

Calibrators Calibration

To be done every 2-years or as required

- AQM R7 Flowmeter Kit - done at TSI in USA

- AQM O3 CAL Ozone Cal source - done at 2B Technology in USA

- AQM R101 Aircal 1000 - done at Aeroqual factory in NZ

- Technical-Note-PID lamp replacement procedure.pdf

![99745fd6-afc8-495e-a1a1-c5fa6c1501aa.png]](https://resources.spectotechnology.com/hs-fs/hubfs/99745fd6-afc8-495e-a1a1-c5fa6c1501aa.png?width=300&height=113&name=99745fd6-afc8-495e-a1a1-c5fa6c1501aa.png)